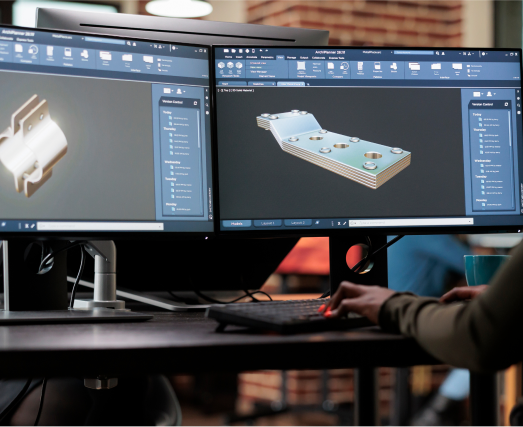

Cultivating manufacturing excellence with AI visual inspection

Automate defect detection with our cutting-edge machine vision softwares

Apex Vision develops highly accurate, application-oriented AI machine vision softwares for defect detection within manufacturing sector. With a core foundation in production engineering and metrology, we specialize in delivering machine learning models tailored for AI visual quality inspection, process control, and anomaly detection in your products and production lines.

Whether it’s electrical, mechanical, instrumentation, or software engineering, we provide the expertise needed to seamlessly integrate cutting-edge AI machine vision algorithms into your manufacturing environment. Our meticulously designed solutions offer colour analysis, pattern matching, edge detection, inspection of surface, measurement of dimensions, presence of components and much more. With over a decade of experience, we deliver robust solutions that drive efficiency, quality, and reliability.

Features

Elevate defect detection with our AI visual models offering best-in-class features

Customizable

Tailor-made algorithms to address specific manufacturing challenges for every unique production scenario.

Flexible deployment

Optimized for seamless integration with edge devices, cloud infrastructure, or Docker.

Scalable

Easily accommodates increased production volumes for your growing needs

Actionable insights

Identifies defects instantaneously, enabling prompt corrective actions.

Solutions

Supercharge your manufacturing with our AI defect detection software suite

Benefits

Harness the advantages of visual AI defect detection in manufacturing

Improved Accuracy

Ensure unparalleled precision, minimizing false positives and negatives, thus enhancing product quality by using AI vision inspection software

Cost Reduction

Reduce production costs by minimizing scrap, rework, and downtime associated with defective products using AI vision

Enhanced Reproducibility

Experience improved reproducibility and reduced human interpretation errors with AI-driven quality inspection, ensuring consistent and reliable results across inspections.

In-line Inspection Excellence

Positioning AI visual inspections in the middle of the production lines ensures high yield by catching defects early, minimizing disruptions, and optimizing throughput.

Reduce time to market

Reduce iteration time during product development thereby improving product quality by detecting and rectifying defects swiftly using AI visual software

Data Insights

Gain valuable insights into your manufacturing processes with AI-powered visual inspection, enabling data-driven decision-making and process optimization.

Case Studies (Real World Applications)

Bespoke machine vision solutions designed for our manufacturing sector clientele

Middle of line inspection for solar cells

Doubled throughput from 120 to 240 units per hour.

End of line inspection for cutting tools

Improved sampling frequency from 9 to 50 measurements per 4000 units

Process monitoring Six Sigma

Significant improvement in quality & notable reduction in excursion frequency

Process Control for sintered products

Reduced set up time by 67% from 30 minutes to 10 minutes