Case study on machine vision enabled process monitoring six sigma

How Apex Vision achieved significant improvement in quality and notable reduction in excursion frequency

In this Six Sigma case study focusing on epitaxial growth, the primary challenges revolved around the need to effectively monitor the quality of epitaxial growth processes and ensure the health of growth reactors. Additionally, there was a requirement to support both Research and Development (R&D) and production groups simultaneously, necessitating a streamlined and comprehensive approach to process monitoring.

Business Needs

- Monitor quality of epitaxial growth.

- Monitor heath of growth reactors.

- Support both Research and Development (R&D) and production groups simultaneously.

Solution

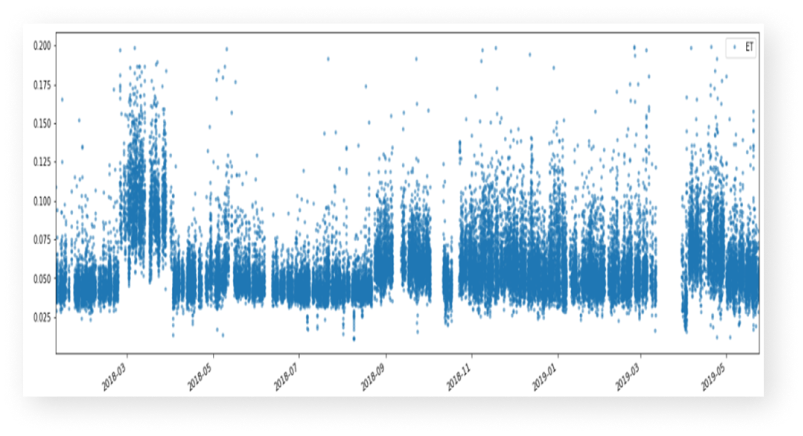

- Established a process monitoring system focused on key parameters critical to epitaxial growth quality to analyze parameters in real-time. This enabled proactive identification and correction of deviations

- Implemented a system to separate production batches, R&D experiments, and excursions, ensuring clear delineation and prioritization of activities. This segregation allowed for focused monitoring tailored to the specific needs of each group, facilitating efficient resource allocation.

- Developed a centralized repository to collate results from various analyses conducted on a per-day, per-reactor basis for a comprehensive overview of process performance.

- Integrated automated alerting mechanisms to promptly notify stakeholders of any anomalies or deviations detected during the monitoring process.

Imapct

- Significant improvements in quality and a notable reduction in excursion frequency by establishing robust process monitoring mechanisms and proactive alerting systems.

- Collation of results allowed for comprehensive comparison between different reactors, enabling the client to identify variations and optimize performance across the production environment.

- Generated data proved invaluable in root cause analysis by facilitating thorough investigations into underlying issues, and implementation of effective corrective actions.